Cheap and Easy Pen Press

If you’re new to wood turning like me, by the time you’ve bought the lathe, chisels, and all the accessories, dropping another $50 on a pen press just seems ridiculous. Before you say “but you don’t know”, I do know; I used one extensively at a friend’s shop and I don’t really see the reasoning behind such an expense.

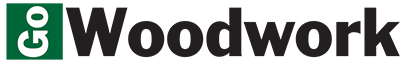

My first idea was to use a toggle clamp but the good quality Bessey ones are close to $30 and that’s really getting close to $50. The second idea was a pipe clamp but again you’re into the $20 range and you will do quite a bit more of work to stabilize a round pipe. I settled on a standard aluminum bar clamp because those can be had for $9.99 at Harbor Freight or even cheaper at some discount tool stores.

- 24″ aluminum bar clamp, $9.99

Amazon (link) has these but they’re twice the price of Harbor Freight - Hardwood

- (1) 1″ x 1-1/2″ x 12″

- (2) 1-1/2″ x 1-1/2″ x 1″

- (1) 1″ x 4″ x 12″

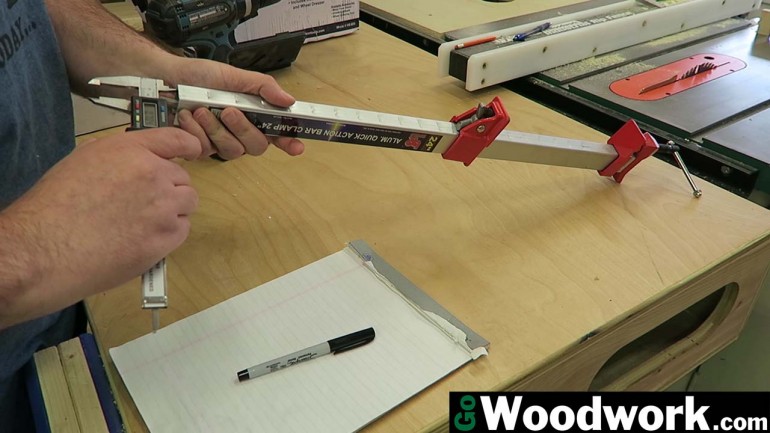

The aluminum bar clamps have one fatal flaw, as torque is applied, the bar will twist from the jaws. First we will solve this by filling the void with hardwood.

Cut the filler strip so that it has a snug fit. Most of these bars are the same in that the open part of the bar slightly bends in so chamfer the edges. The opposite side needs a recess cut due to the stop notches on the bar being pressed down.

After fitting the strip to the bar, I cut the bar down to about 12″. This should be more than enough to assemble most pens.

On the clamp I used, the stationary jaw sat slightly higher than the moving one. I notched out an area so it would sit more evenly.

The clamp used a rivet to contain the movable jaw but since that was cut off, I replaced it with a standard 1/4″-20 hex bolt. This also keeps the hardwood in place

I cut the base (easier to clamp it down to your bench) and pre-drilled for screws.

Since the rear of the clamp was still slightly lower than the front, washers were added to keep the clamp more stable.

Hardwood pads were cut and attached to the clamp using CA glue before adding 1″ #4 screws through the clamp and into the wood. The pad on the movable jaw has a 1/4″ hole bored dead center to hold various pen parts during assembly. Flat parts such as pen caps going into the body can simply be assembled offset from center.

The press doesn’t need to be clamped down but I find it easier that way. You could always attach some type of rubberized traction pad such as FastCap Traction Dots.

To use the press, simply follow the instructions included in your pen kit. At first you will notice there is some play in the mechanism simply due to the shoddy construction of these clamps but you will also quickly see how easy it is to use.